On viral quick-fixes for the logistics crisis

Original Twitter thread here: https://twitter.com/opendna/status/1452064375938891777

Related Twitter thread here: https://twitter.com/opendna/status/1454187317397233673

I checked into the claims in this port thread. While the facts are broadly correct, the policy response is not. I’m going point to some other possible choke-points, suggest solutions, and explain why some of the suggestions are counter-productive.

Yesterday I rented a boat and took the leader of one of Flexport’s partners in Long Beach on a 3 hour of the port complex. Here’s a thread about what I learned.

— Ryan Petersen (@typesfast) October 22, 2021

The alleged bottleneck is a shortage of chassis. They’re the trailers that containers ride on from the ports to warehouses. In the LA region, the three main rental firms operate a “Pool of Pools” of 80,000 chassis. (DCLI/Pool of Pools – LA/LB)

If the chassis crunch is correct, there are >80,000 empty containers around the LA port complex. Stack the empties five high on the Mexican border and we could build a wall 100 miles long. Recent import/export trends suggest empties are growing at a rate of about 20K/month.

The chassis rental firms know they don’t have enough equipment and have been investing heavily. Trump’s trade war with China took the largest global manufacturer out of the market and US producers haven’t been able to ramp up production to meet demand.

DCLI, one of the largest members of the Pool of Pools, says customer are keeping chassis ~70% longer than normal. But for that delay, there’d be adequate chassis supply today. They believe customers are holding chassis longer because there isn’t labor to unload at warehouses.

However, it is true that terminals are so full that they’re refusing to accept empty containers. Some are not accepting any empties, some only certain sizes, and some only if you take a container back out. i.e. APM Terminals’ update: apmterminals.com/en/los-angeles…

Both ports have an IT system where registered companies can get a live update of which terminals are accepting which container types. track.portoptimizer.com i.e. COSCO at Long Beach Container Terminal will trade standard 20′ and 40′ but won’t take 40′ high-cube.

This means that a trucker with an empty 20′ COSCO container on a chassis can trade it for a full 20′ COSCO container at the LBCT. A trucker with 20′ OOCL empty however, will be turned away at the LBCT gate. OOCL’s only trading 40′.

Remember that “one trucking partner alone has 450 containers sitting on chassis right now”? The one who wants to stack empties five high? 1) they must have empties they can turn in and trade for full loads. 2) they haven’t grounded containers and stacked them two high yet.

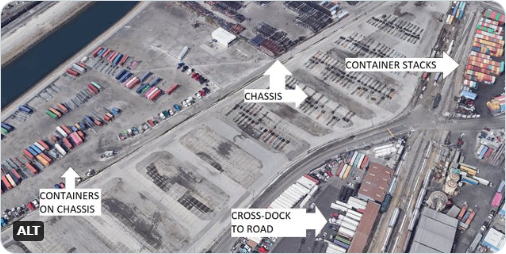

It’s not uncommon for logistics firms to have large numbers of containers on chassis in their yard. It’s not uncommon for them to hoard empty chassis to save time. This is an undated image from Google Earth from near the PoLA/LB complex shows normal.

State and federal orders to run ports 24/7 will increase the number of chassis waiting in truck yards because truckers who pick up loads at night/on weekends and can’t deliver them to closed warehouses will have to drop them in yards until customers open for business.

So I believe some of the suggestions in that thread are counter-productive. We need the trains taking containers out of the region as fast as possible, not being diverted to run loaded freight 100 miles inland (increasing the number of empties).

If we’re going to take advantage of 24/7 port operations, we need space for laden chassis to stage during off-peak hours. We don’t want to fill truck yards with stacks of empties which can’t be returned. If anything, we should be dumping *empties* inland, not loaded containers.

The ports are a choke point in a complex system soaked in market failures: conflicting interests, moral hazards, tragedy of the commons, oligopoly pricing and monopsony labor, and nothing close to perfect information. And every lobby is trying to turn this crisis to advantage.

Citing the port crisis trade associations lobbied Sacramento to suspend labor laws (AB 701 and AB 5), vaccine mandates, EIR requirements, and called for aggressive action against homeless encampments. On Twitter we saw agitation to suspend zoning rules.

So I’m getting the impression that logistics firms aren’t being entirely candid with shippers or the public. Why aren’t warehouses running 24/7? Why are loaded containers waiting in yards? Are they having labor shortages? What’s with the attack on wages & working conditions?

If businesses are making demands on government, blaming everyone from the mayor to the president, while NOT doing everything they can to alleviate the supply chain crunch – including raising wages and improving working conditions – then we need to ask if maybe they’re on strike.